MEMS microphone is fabricated from one side of the planet to the other, remembering for areas like Germany, Mexico, and Japan. The MEMS microphone is a simple and easy to-utilize mic for different sound-tactile applications. The installed miniature microphone is an omnidirectional, low-impedance, detached microphone with a simple information. It's great for applications where the client needs to get a word or expression and record it, just as catching encompassing sounds for later playback.

The MEMS microphone is constructed like a large jack with a small sliding plate on one side and a flexible ribbon on the other. To use the device, one inserts a flexible ribbon into the jack and plugs the flexible tip into the provided mounting bracket. One then places their hand over the top plate and activates the microphone. A mechanical cover permits sound waves to pass through the MEMS microphone and reach the recording head. This allows the user to control the volume and pan of the recording. In regions such as Germany, the increased usage of smartphones has increased the production of MMS microphones. For instance, according to Global System for Mobile Communications Association in 2020, there were around 60.74 million smartphone users in Germany.

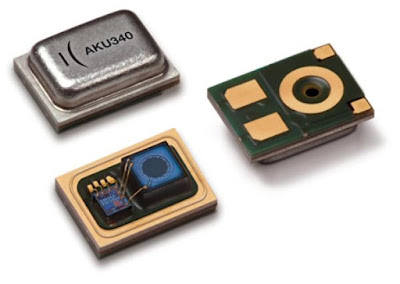

In contrast to customary unbending microphones, MEMS microphones have a slender layer of silicon within the plate. Silicon is a semiconductor that has the properties of conductivity, resistance to harm from vibration, and warm extension. Silicon's exceptional electronic properties permit it to be contracted to tiny measurements. By utilizing a mix of temperature and pressing factor, the skinny layer of silicon can be made to frame a layer of fluid that is profoundly receptive to sound waves. The fluid's electronic properties permit the client to exactly control the thickness and width of the backplate.

The assembly process produces a very thin sheet of silicon that can be used in conjunction with heat and pressure to form a very durable, flexible membrane. By using the electrical signals from the microphone to power a variety of different equipment components, MEMS microphones can provide several high-frequency output power levels. Some MEMS microphones have even been used to power cell phones. The electrical signals produced by the microphone may consist of low-frequency noise, high-frequency sound waves, or a combination of the two.

No comments:

Post a Comment